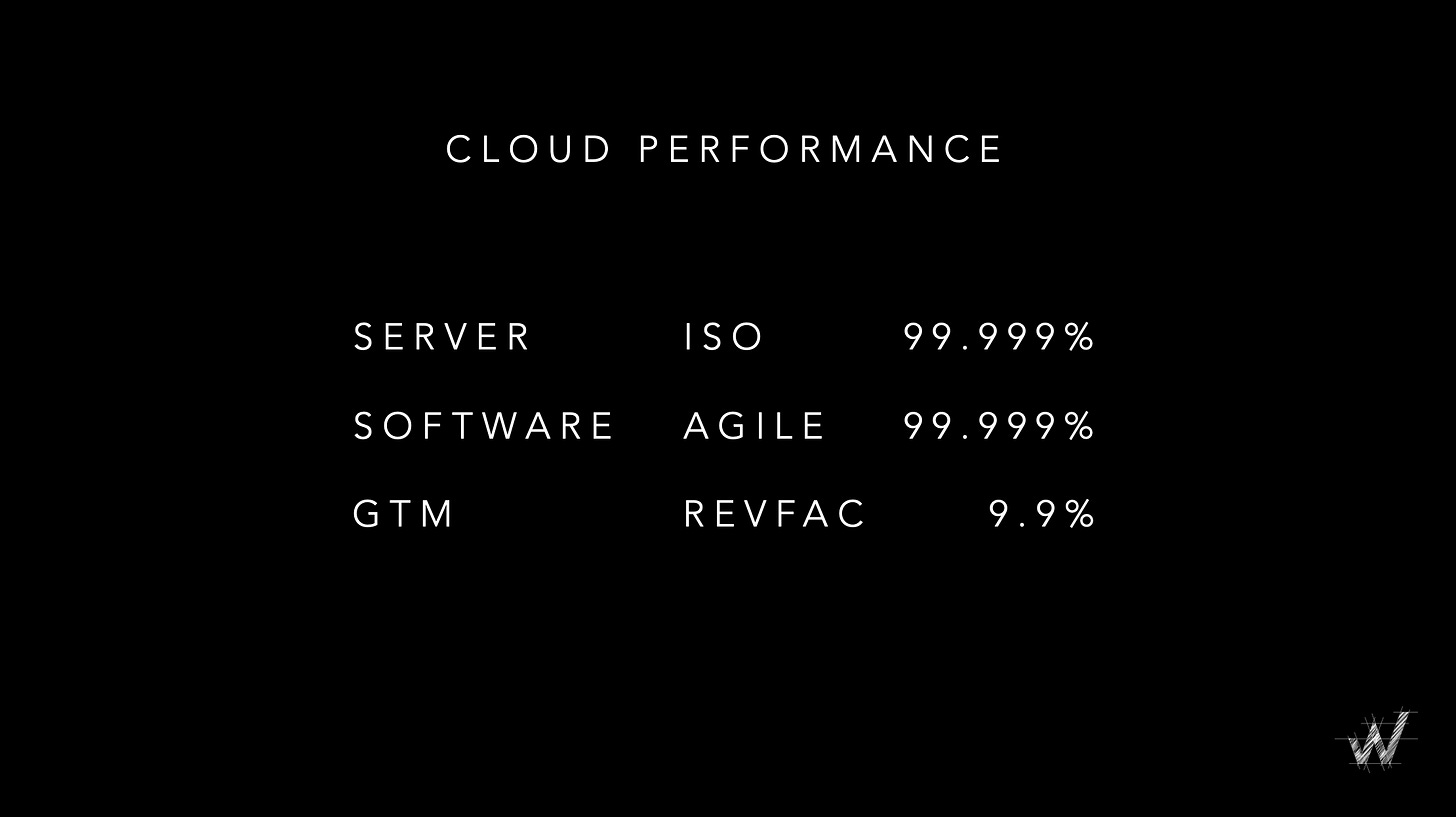

Ever wonder why so many parts of our economy operate to such rigorous standards (99.999% quality, or five-9s), whereas GTM—arguably the most important factor in whether a company succeeds or not—operates so haphazardly? By comparison: the success outcome of SaaS companies who have raised at least $3M (and therefore have presumably build a product) is 1.7%. Not even one 9. Not even close.

This week was PLGTM, a conference for GTM nerds in San Francisco. I gave the closing keynote, which is captured here on video (from my home office), and summarized below in text. I’ve also included a link to the slides in .ppt, which file includes all the animations too. Not that you’ll ever use them, but feel free!

Craft vs. Mass vs. Lean Manufacturing

Craft manufacturing is a means of production, whereby the outcome depends on the skills of the individual. Mass manufacturing adds process and standardization, which results in higher throughput and higher quality. Lean manufacturing adds automation and data, and it relies on fewer humans and more robots.

All three methods are in play today, in 2024:

Principles of Lean Manufacturing

How is it that a Corolla can be produced in such high volumes (300,000 per year) at such a low cost ($30K) and at such high quality (300,000 lifetime miles expected)?

And why are no parts hand-fitted on the Corolla?

Lean manufacturing rests on 5 principles:

Value: Products are designed with only features that customers value and therefore will pay for.

Value Streams: Every step in the lean manufacturing process is designed to contribute to value customers will pay for. If a step does not contribute end-customer Value, it is designed out of the process.

Flow: The production process flows continuously—no starts and stops, no hiccups.

Pull: Products are produced “just in time.” Buying signal from the market “pulls” product through the manufacturing process, not the other way around.

Perfection: The whole process is continuously optimized. “Don’t bolt down what you can tape down, and don’t tape down what you can hold down.” Processes are tested, perfected, and then hardened into the system. This is why no parts are hand-fitted on a Corolla. Everything has been through this quality process.

SaaS’ “Moment”

We’re having a moment. 2022 and 2023 were horrible for SaaS. Growth rates have been cut in half, and the little growth we are seeing costs more than ever to achieve.

Paying $2.54 for every $1 in net new ARR is unsustainable. We call it GAAC (growth at all cost, pronounced “Jack” for reasons you will see if you watch the video), and it is not only unsustainable, but unsuccessful. 1.7% success rate is a failing grade on any scale (see intro).

The Lean Revenue Factory

Revenue production can be looked at through a similar lens. If we were to design a Lean Revenue Factory, according to lean principles, what would that look like?

First off, we would organize our factory, with each GTM motion being its own production line. Each production line has its own input, throughput and output, and each line is measured independently, according to the expectations of that particular GTM.

Revenue Architecture

To architect each production line by design, and according to our desired results, we will need three things:

Data Model—this will apply to the entire factory. We will use this to normalize results across GTMs and measure and monitor results

GTM Model—this will be per GTM… each according to its target customers and ACV

Growth Formula—this is the set of mathematical targets that define success within a GTM

Data Model

The Data Model describes and quantifies each step in the customer journey, from awareness through to expansion. A single data model can be used to organize inputs, throughput and outputs across multiple GTMs and help analyze and compare efficacy.

GTM Model

Each GTM motion is described by its processes—not only on the left side of the bowtie for new customer acquisition, but also on the right-hand side, where all the compound growth happens.

The processes for serving a no-touch (PLG) customer are very different than the processes that serve a high-touch (outbound) customer. These processes must be designed, executed and measured independently in the sphere for which they are intended.

Growth Formula

And finally, for our Lean Revenue Factory, we need to be deliberate about the math within each GTM and what is required for success.

We call this a Growth Formula, and it is all normalized to a single customer (the “1” at the center of the picture above). What does it take to produce a single customer? That is everything to the left of the “1.” And what does that single customer produce in terms of revenue (everything to the right of the “1.”)

Each GTM has a different Growth Formula that defines success, but they can all be tracked within the same data model and analyzed according to ratios (like CAC ratio, or LTV-to-CAC, or CAC payback) that transcend across GTMs.

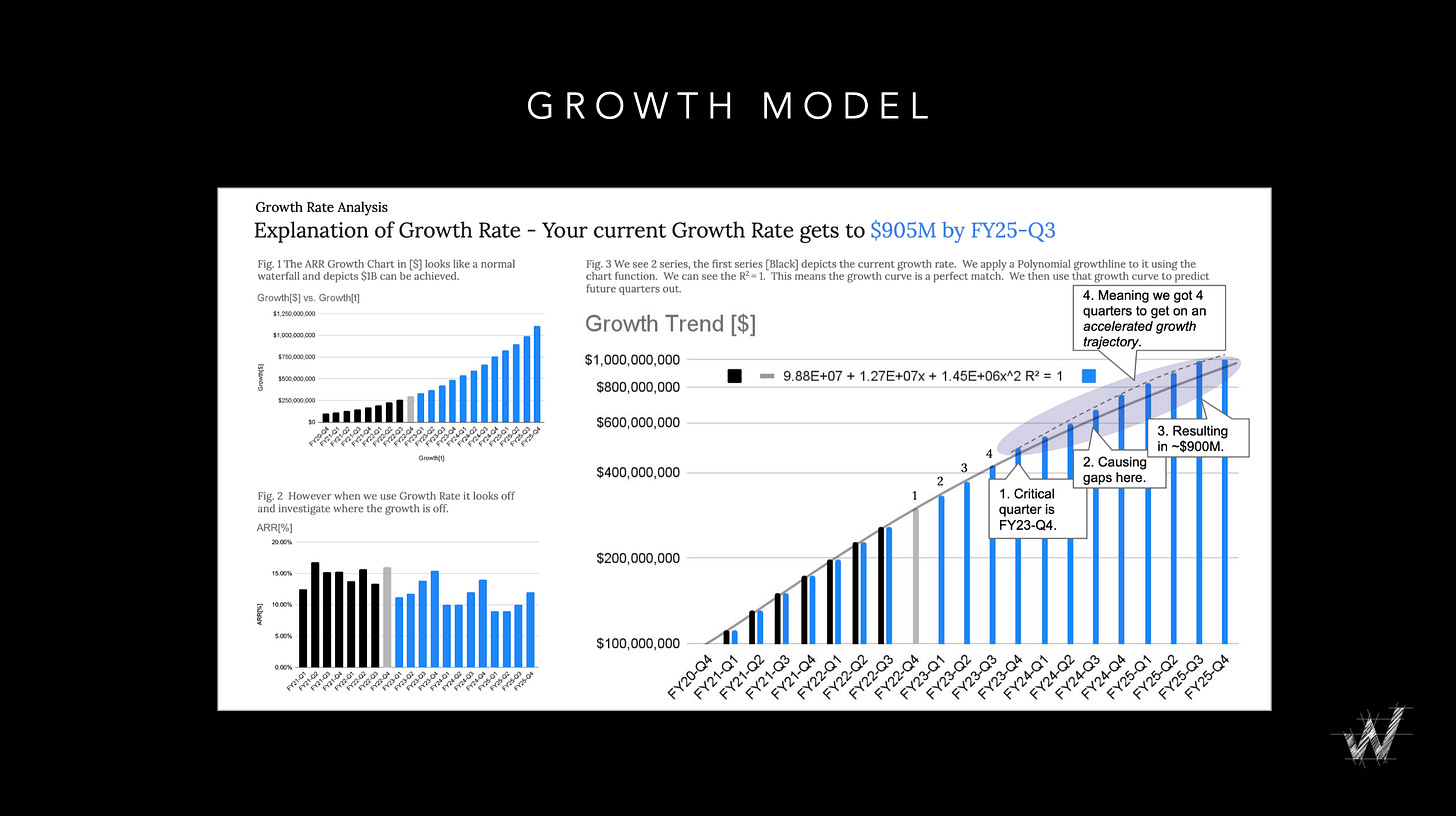

Growth Model

Now that we have each GTM designed (GTM Model + Growth Formula) and measured (Data Model), we can aggregate them into a single picture of growth for the entire company. This is the Growth Model.

When any given GTM is in its sweet spot (the steep part of the S-curve), we know we have tuned the process (first held down, then taped down, then bolted down), and we have a robust system for producing high volumes of high-quality revenue at sustainable cost. When this is the case, we can afford to look ahead to adding another GTM. This not only diversifies our sources of growth, but it protects us somewhat against the inevitable growth attenuation of a single GTM as we reach saturation.

Hit the Road, GAAC

When done correctly, building a Revenue Factory according to the principles of Revenue Architecture can produce multiple, high-performance revenue production lines. Just as Toyota has over 30 vehicles, each produced according to a lean manufacturing process, and each produced at high volume, low cost, and high quality, we can do the same with revenue.

But it is up to us—the systems thinkers. The GTM nerds. The ones who think beyond “just” PLG or “just” sales and architect GTM success from the ground up.

If we do this, we can free ourselves from GAAC, which is producing a 1.7% success rate. We will build Revenue Factories, which can produce two 9s: 9.9% success rate. Let’s start there! What a different world we will live in!

Hit the road, GAAC. The Revenue Architect is the new sheriff in town.

XOXO,

-db

Click below to access the PowerPoint slides used in this keynote.

Don’t drive angry.